Product Overview

Downloads

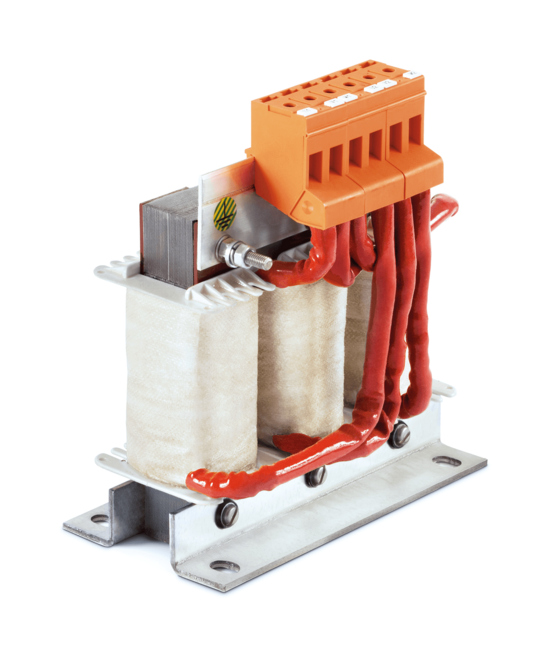

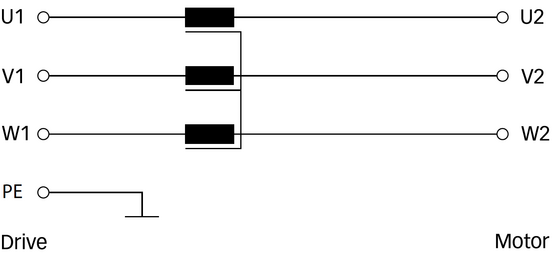

Three-phase dv/dt reactor for motor protection

- Reduction of drive output voltage dv/dt

- Reduction of motor temperature

- Increase of motor service life

- Compact and economic open frame design

- Standard catalog reactors up to 1100 A

- UL rated materials used

Features and Benefits

Efficient reduction of high output voltage dv/dt from IGBT motor drives

Typical Applications

Servo drives

Technical Specifications

Maximum continuous operating voltage

3x530 VAC

Nominal operating voltage

3x500 VAC

Rated currents

4 to 1100 A @ 40°C

Overload capability

2 x rated current at switch on for 30 seconds

1.5 x rated current for 1 minute, once per hour

Typical dv/dt reduction

≥factor 5

Impedance (Uk)

0.8% @ 400 VAC, 50 Hz and rated current

Motor frequency

0 to 60 Hz

Motor cable length

30 m max. @ 16 kHz (see derating curve page 2)

Switching frequency

fPWM 2 to 16 kHz

High potential test voltage

P –> E 3000 VAC for 3 sec

P –> P 3000 VAC for 3 sec

Overvoltage category

OV III (IEC 60664-1)

Temperature range (operation and storage)

-25°C to +100°C (25/100/21) operation and storage

Protection category

IP 00 (KL types according to VBG 4)

Flammability corresponding to

UL 94 V-2

Design corresponding to

EN 61558-2-20 (VDE 0570-2-20), UL 508C, CSA C22.2 NO. 14

Insulation class

T40/N (200°C) for ≤182 A types

T40/F (155°C) for ≥230 A types

MTBF (Mil-HB-217F)

>500,000 h @ 45°C/480 V