Product Overview

Downloads

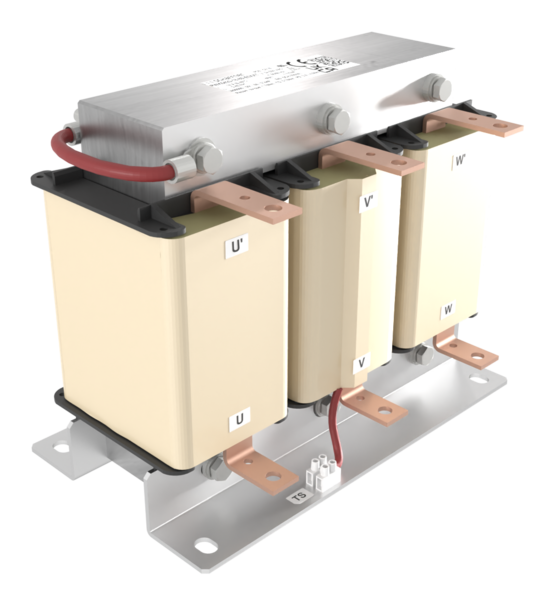

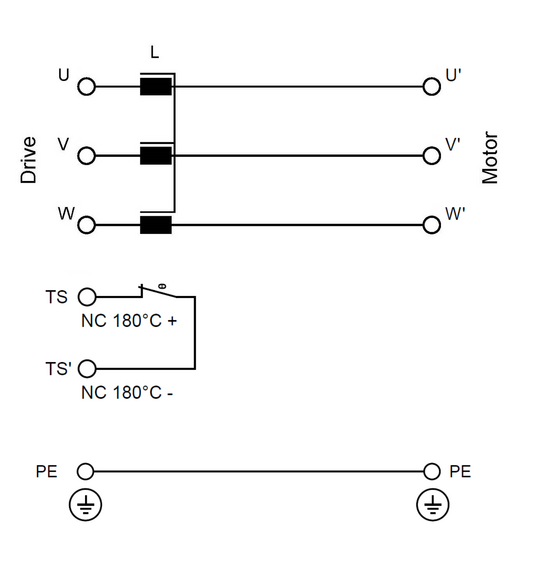

Three-phase dv/dt reactor 6% for motor protection

- Reduction of drive output voltage dv/dt

- Reduction of motor temperature

- Increase of motor service life

- Compact and economic open frame design

- Standard catalog reactors up to 1000 A

- UL rated materials used

Features and Benefits

Converts the rectangular PWM output voltage of motor drives into a smooth sine wave with low residual ripple

Elimination of premature motor damage caused by high dv/dt, overvoltages, cable ringing, motor overheating, and eddy current losses

Improves bearing life time because of bearing currents caused by circulating currents

Complies with IEC 60034-17* requirements for general purpose motors

Typical Applications

HVAC applications

Pumps

Conveyors

Compressors

Elevators

Cranes

Medium voltage applications, deployed in front of the step-up transformer

Retrofit installations with motor drives

Motor drive with long motor cable

Motor drive with multiple motors in parallel

Technical Specifications

Maximum continuous operating voltage

3x530 VAC

Nominal operating voltage

3x480 VAC

Rated currents

2.3 to 1000 A @ 45°C

Overload capability

1.5× rated current for 1 minute, once per hour

Residual ripple voltage

<5%

Impedance (Uk)

6% @ 400 V, 50 Hz and rated current

Motor frequency

0...60 Hz (up to 200Hz with derating, see user manual)

Motor cable length

Max. 100m depending of switching frequency (see user manual)

Switching frequency

fPWM 0 to 16kHz

High potential test voltage

P –> E 2480 VAC, 1 s

Overvoltage category

OV III (IEC 60664-1)

Pollution degree

3

Temperature range (operation and storage)

-40°C to +45°C fully operation

+45°C to +100°C derated operation*

-40°C to +100°C transport and storage

Climatic category

40/070/21

Protection category

IP 00

Flammability corresponding to

UL 94 V-2

Design corresponding to

EN 61558-2-20 or EN 60076-6

MTBF (Mil-HB-217F)

>500,000 h @ 45°C/480 V

* Iderated = Inominal*SQRT((Tmax-Tamb)/(Tmax-Tnominal)) = Inominal*SQRT((100°C-Tamb)/25°C)