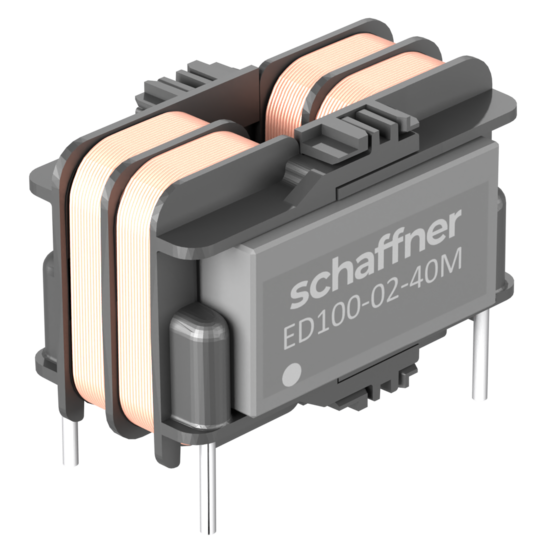

Lighting LED drivers need to be high in efficiency, low in cost and compliant to EMC regulations. The ED100 / ED101 series increases the efficiency of a LED driver circuit by reducing the need for X-capacitors. Thus, the power factor rises, and less unwanted reactive power is generated. The inductor is a combination of a strong common-mode inductance with a significant differential-mode inductance. It offers two filtering elements in one component. This helps the circuit designer to reduce the number of elements on the PCB, to reduce space requirement as well as lowering costs. Combined with the high MTBF value of the ED100 / ED101 series, a circuit design with reduced number of components profits for its overall reliability and lifetime.

Current-compensated choke series for lighting applications

Articles

| Article | Rated Current @ambient | Inductance | Input/Output connections (Nm) | Distribution stock | Compare | Read More | |

|---|---|---|---|---|---|---|---|

| L1 | Input terminal | ||||||

| ED100-0.2-40M | 0.2 | 40 | PCB Pin | |||

| ED100-0.3-27M | 0.3 | 27 | PCB Pin | |||

| ED100-0.4-20M | 0.4 | 20 | PCB Pin | |||

| ED100-0.5-15M | 0.5 | 15 | PCB Pin | |||

| ED100-0.75-12M | 0.75 | 12 | PCB Pin | |||

| ED100-1-9M0 | 1 | 9 | PCB Pin | |||

| ED100-1.25-7M0 | 1.25 | 7 | PCB Pin | |||

| ED100-1.5-5M0 | 1.5 | 5 | PCB Pin | |||

| ED100-2-3M0 | 2 | 3 | PCB Pin | |||

| ED101-0.2-40M | 0.2 | 40 | PCB Pin | |||

| ED101-0.3-27M | 0.3 | 27 | PCB Pin | |||

| ED101-0.4-20M | 0.4 | 20 | PCB Pin | |||

| ED101-0.5-15M | 0.5 | 15 | PCB Pin | |||

| ED101-0.75-12M | 0.75 | 12 | PCB Pin | |||

| ED101-1-9M0 | 1 | 9 | PCB Pin | |||

| ED101-1.25-7M0 | 1.25 | 7 | PCB Pin | |||

| ED101-1.5-5M0 | 1.5 | 5 | PCB Pin | |||

| ED101-2-3M0 | 2 | 3 | PCB Pin |

Features and Benefits

Typical Applications

Technical Specifications

Rated currents

0.2 to 2 A @ 65°C

Operating frequency

DC to 60 Hz

Creepage and clearance distances

Creepage > 3 mm / Clearance > 2.5 mm between windings

Rated inductance

3 to 40 mH common-mode

Operating voltage

300 VAC, 50/60 Hz

Overvoltage category

II acc. IEC 60664-1

Pollution degree

PD2 acc. IEC 60664-1

Stray inductance

0.1 - 3.1 mH

Inductance reduction (DC bias with IN)

Less than 10% at rated current

Temperature range (operation and storage)

-40°C to 125°C

Climatic category

40/125/56 acc. IEC 60068-1

Cooling

AN - natural convection

Altitude

Derating above 2,000 m

Protection category

IP 00

Flammability corresponding to

UL 94 V-0

Vibration and shock

3M4 acc. IEC 60721-3-3

Design corresponding to

IEC 60938-1/-2

MTBF (Mil-HB-217F)

>13,000,000 h @ 65°C/250 V